Crimping system overview

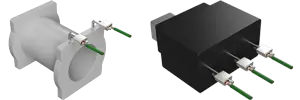

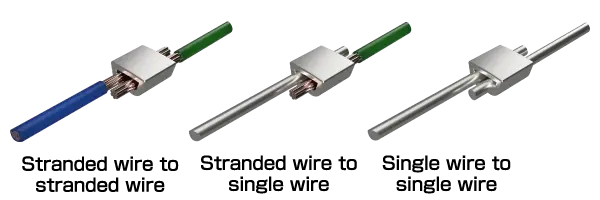

This crimping system is effective for connecting wires to each other, wires to lead wires, and lead wires to each other.

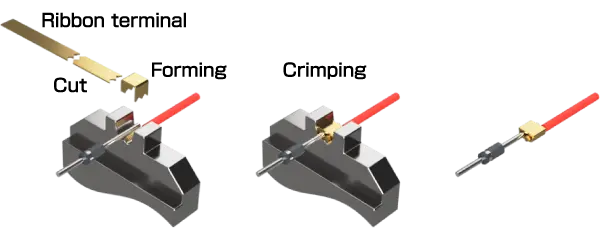

ICREX's crimping system is a highly reliable connection method that consists of a ribbon terminal that becomes a crimp terminal, an applicator that converts the ribbon terminal into a crimp terminal, and a ribbon crimper that drives the applicator.

Image of crimping process

Crimping machine ribbon crimper

Crimping system features

Stability of quality

Compared with manual soldering, which has a large variation in quality due to the degree of skill, crimping systems do not require skill because they are mechanically connected.

Extremely little variations in quality caused by operators, and stable connections can be obtained.

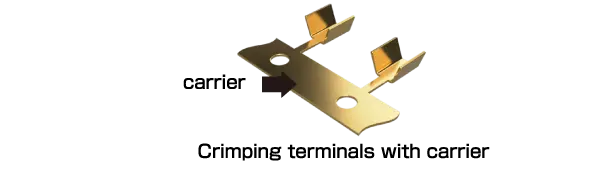

No scrap comes out

Unlike terminals with carriers, crimping with ribbon terminals does not require a carrier, so there is no scrap.

Many parts that can be crimped

When crimping with a crimping system (ribbon crimper), the workpiece does not interfere with the carrier or adjacent terminals, unlike when crimping terminals with carriers.All you have to do is set the workpiece to be crimped onto the lower mold called the crimper, so you can crimp a variety of workpieces. You can connect various workpieces, such as connecting switches or coil bobbin lead wires to electric wires.