About ICREX

his is a company that offers proposal-based products in custom production that lead mainly to the solution of board connection problems.

We develop and produce parts based on our custom standard product group, which has been cultivated over many years to solve problems such as "Isn't it possible to make such a part? I wish I had such a part."

It has been used in many cases where "off-the-shelf standard products do not meet the specifications, or there are no standard products in the first place."

- Design, manufacture and sale of connection terminals

- Design, manufacture and sale of terminal insertion systems for connections

- Design, manufacture and sale of crimping terminals and crimping machines

- Design, manufacture and sale of electrical connection parts

- Design, manufacture and sale of automatic parts for electrical connections

There is no sales office. The Head Office will respond.

Most of our products are manufactured at our headquarters.

The business hours will be from 9:00 to 17:30, excluding the basic weekends and holidays.

However, the year-end dawn and Golden Weak are not working.

You can send it at any time from the form email on the home page.

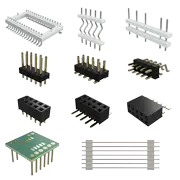

Overall product guide

Basically, there are no standard or inventory products because they are made to order for custom products.

All products are RoHS compliant.

At ICREX, we provide standard products that serve as the basis for a wide variety of custom products as the basis for creating solution products.

Use primarily to connect boards

Mainly used in the connection between substrates and molded products

Be used by mounting on a substrate

Primarily join wires together

In addition

There is no price list because it is a uniform custom product.

The minimum lot of Semi-Custom Pin Headers and Female Headers is 3000 except for the prototype.

For other products, we do not decide in particular, so please consult with us.

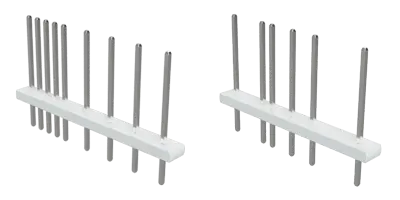

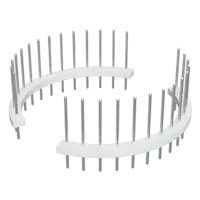

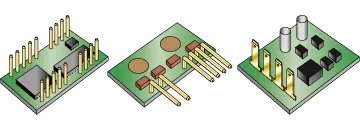

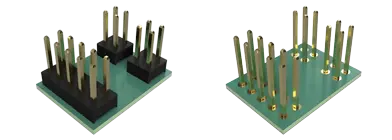

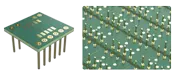

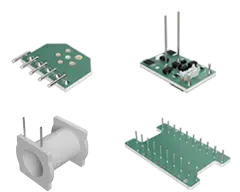

Full Custom Pin Headers

Proposal-based products that lead to the solution of board connection problems.

This pin header solves such problems as "the thickness, length, shape, and pitch of the terminal," "it is difficult to use with standard pin headers made off the shelf due to the specifications," and "it cannot be found with existing products."

Since the base part is a board material, the pitch between terminals and the shape of the base part can be flexibly set, and it is resistant to heat and can reduce the initial cost.

Flexible terminal pitch

Flexible base shape

Various types of pins can be used, or different pins can be combined.

Round

Square

Flange

Right angle

Wave

Combination of different terminals

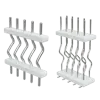

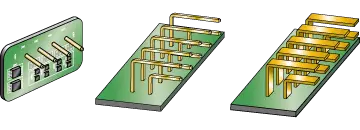

Wave pin headersReduces stress on solder parts due to thermal stress and temperature changes

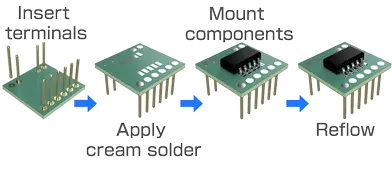

Wave pin headersReduces stress on solder parts due to thermal stress and temperature changes SMT type pin headersChange the board module to SMT type

SMT type pin headersChange the board module to SMT type Through hole contact pin headersConnect to through-hole without soldering

Through hole contact pin headersConnect to through-hole without soldering Snap off pin headersLeaving only the terminals after soldering

Snap off pin headersLeaving only the terminals after soldering Conversion adaptersConverts the pitch and arrangement of electronic components, etc. Also effective as a countermeasure for discontinuing the production of parts.

Conversion adaptersConverts the pitch and arrangement of electronic components, etc. Also effective as a countermeasure for discontinuing the production of parts. There are other product examples as well.Even if this is not the case with the product, we will also consider consulting about the possibility of such pin headers.

There are other product examples as well.Even if this is not the case with the product, we will also consider consulting about the possibility of such pin headers.

We will also consider resin molded products.

Semi-Custom Pin Headers

Pin header that allows you to specify dimensions and remove unnecessary pins.

We have a wealth of basic specifications that serve as a customizable base for each pitch of 0.8㎜, 1.0㎜, 1.27㎜, 2.0㎜, and 2.54㎜.

It is possible.

It is possible.

However, it may not be possible depending on the number of contacts and the height.

Please contact us.

Female Headers

Female header on the mating side of the pin header. Also known as a pin socket.

It can be used in combination with our Semi-Custom Pin Header.

It is possible.

However, it may not be possible depending on the number of contacts and the height.

Please contact us.

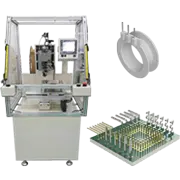

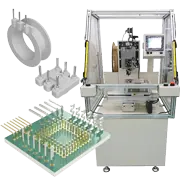

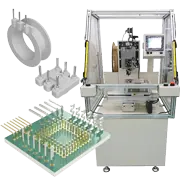

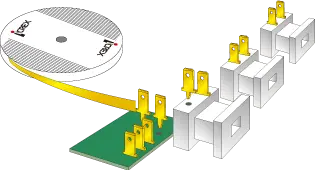

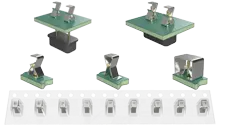

Preform Chain Terminal Insert Systems

This is a system for directly inserting terminals into circuit boards or molded products. It consists of a continuous terminal and a continuous terminal insertion machine.

Separate the continuous terminals one by one and insert the terminals directly into molded products such as printed circuit boards and bobbins.

We offer preform chain pin terminal insert system and preform chain tab terminal insert system.

This system is mainly used as a mechanical component for electrical connection between printed circuit boards and as a terminal for bobbin winding.

- Electrical mechanism parts for external connection of board modules

- Terminals for connector connection

- Electrical mechanism parts for connecting boards to each other

- Bobbin winding terminal

It is used for such things.

- Terminals can be inserted without cutting the collective board into individual pieces.

- Since the terminal is inserted directly into the workpiece, no insulator is required, saving space.

- Terminal shape is gentle on workpieces, as the tip of the pin does not scrape the pilot hole of a printed circuit board or molded product when inserting the terminal.

- A method that allows soldering to be completed on a reflow line is possible (conditions apply)

- Unlike terminal insertion tools, the pitch and position of inserting the terminals can be determined by the insertion machine program.

The Preform Chain Pin Terminal Insert System, which constitutes the Preform Chain Terminal Insert System, is a system in which pin terminals connected vertically in a chain are separated one by one by a terminal insertion machine and directly inserted into a printed circuit board or bobbin.

This is a vertically connected continuous pin terminal. It is wound on a reel.

As long as it is within the basic specifications, you can specify the length and thickness of the terminal without any initial cost.

We also have the option to add flanges and other processing depending on the application.

The tip of the terminal is pyramid-shaped and will not damage the hole in the workpiece when inserting the terminal.

By adding star processing to the press-fitting part of the pin terminal, the adhesion strength can be increased.

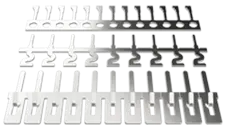

The Preform Chain Tab Terminal Insert System is a system in which continuous tab terminal made by press processing are separated one by one by a terminal insertion machine and directly inserted into a printed circuit board or bobbin.

This is a custom tab terminal made by manufacturing a press die.

There are no standard or off-the-shelf products.

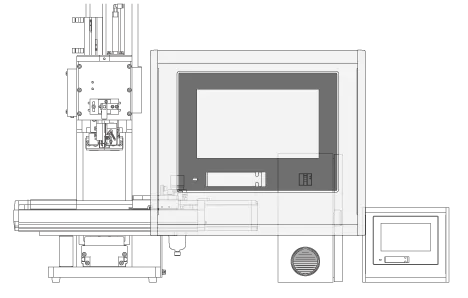

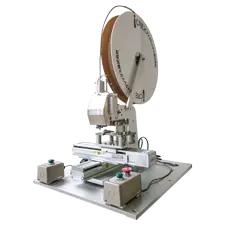

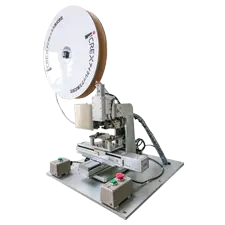

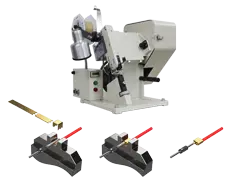

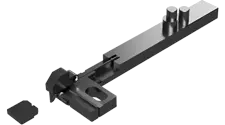

This machine inserts a preform chain terminal made by ICREX into a workpiece.

For the preform chain pin terminal, the desktop type and the stationary type are available as standard machines. Custom models with a workpiece loading/unloading unit are also available.

Custom support is available for the preform chain tab terminal.

We do not sell only the Preform Chain Terminal Inserter.

Use of the terminal made by ICREX is a condition.

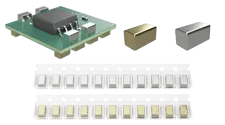

Custom SMT Parts & Components

SMT bottom entry terminalsThat allows components to be attached from the back side of the printed circuit board

SMT bottom entry terminalsThat allows components to be attached from the back side of the printed circuit board Block TerminalsThat can be used as electrical connection parts and heat dissipation parts.

Block TerminalsThat can be used as electrical connection parts and heat dissipation parts. Plate TerminalsThat can be used to strengthen contacts, etc.

Plate TerminalsThat can be used to strengthen contacts, etc. SMT JumpersThat can be used to bypass the board pattern

SMT JumpersThat can be used to bypass the board pattern SMT adapterThat converts discrete parts or parts not for SMT to SMT using lead terminals and printed circuit board materials

SMT adapterThat converts discrete parts or parts not for SMT to SMT using lead terminals and printed circuit board materials

Custom parts that allow lead-type parts or board modules to be mounted on through-hole boards or single-sided boards from the back side.

Custom terminals that can be used for mechanical parts for connecting board modules, heat dissipation parts, etc.

This is a plate-type custom terminal with no burrs all around, which can be used to strengthen board pads or as a substitute for partial gold plating.

This is a custom-made SMT jumper terminal that can be used to bypass the PCB pattern.

This is a custom-built adapter that converts non-SMT parts to SMT using lead terminals and base material.

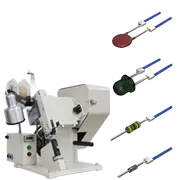

Crimping System

This crimping system is effective for connecting wires to each other, wires to lead wires, and lead wires to each other.

This highly reliable wiring system consists of a ribbon terminal that becomes a crimp terminal, an applicator that converts the ribbon terminal into a crimp terminal, and a ribbon crimper that drives the applicator.

ICREX Crimping Systems are used in a variety of fields, including home appliances, automobiles, and telecommunications equipment.

- Temperature sensors such as thermistors, temperature fuses, temperature-sensitive reed switches, and thermocouples

- Display or illumination using LEDs

- Connection with electronic components such as resistors, diodes and capacitors

- Compared to manual soldering, the quality is more stable because the wires are connected mechanically.

- Compared to crimping with formed terminals, the range of workpieces that can be crimped is expanded.

- No scraps

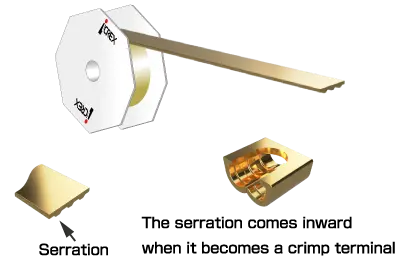

The Ribbon Terminal is a strip-shaped terminal wound around a reel that attaches to the crimper ribbon crimper.

It eventually changes to a crimp terminal.

The Ribbon Terminals are serrated in a wave shape and are designed to increase the area of contact with the workpiece to be crimped. This serration improves electrical properties such as contact resistance and mechanical properties such as tensile strength.

The applicator is a tool attached to the ribbon crimper of a crimping machine that cuts and forms ribbon terminals into crimp terminals.

The size of the crimp terminal is determined by the applicator, and the type of applicator is determined by the size of the work to be crimped.

This is a machine that drives the applicator to convert ribbon terminals to crimp terminals and connects workpieces in about 0.2 seconds.

It is possible. Consult us.

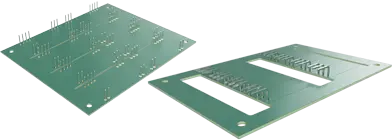

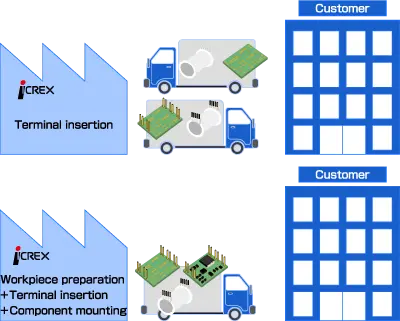

Printed circuit board with terminal

This is a product that can reduce the amount of work required to attach terminals later.

Printed circuit boards with terminals attached in advance will be manufactured.

This product is possible because we handle everything from terminal production to terminal insertion as a system.

Can be handled.

The know-how gained through the terminal insertion system prevents the terminal from falling off the board by providing an overhang on the terminal itself and fitting it into the board through hole.

The soldering method differs depending on the state of insertion of the terminal. For details, please consult us.

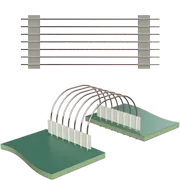

Flexible board connectors

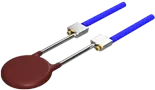

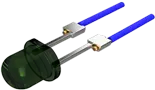

This is a component that can flexibly connect boards realized by using magnet wires in the conductor section.

The degree of freedom in the connection form between boards is improved.

The board can be installed in various arrangements after the board flexible connecting parts are soldered.

It is thin.

Custom specifications such as length, number of contacts, and pitch are available.

There is FiP-01 which is easy to bend in all directions. Also, please consult us regarding specifications that do not apply to FiP-01.

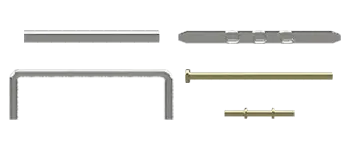

Pin Terminals, Lead-Pin

Custom made pin terminals

It is manufactured in custom specifications such as size, bending, and plating.

It is possible to perform header processing, crushing processing, U-shaped bending, crank, flange processing, etc.

Mini-Jumpers

1.27㎜、2㎜ and 2.54㎜ pitch open and closed types are available.

Assembly Service

ICREX's assembly service, which uses terminal manufacturing technology and terminal insertion technology, will respond to requests such as "I want a product with terminals inserted" and problems such as "I want to insert terminals, but it is difficult to install equipment."

It is possible from terminal insertion or terminal insertion to soldering or terminal insertion to component mounting on a workpiece.

We can also prepare the workpiece.

Consult us.

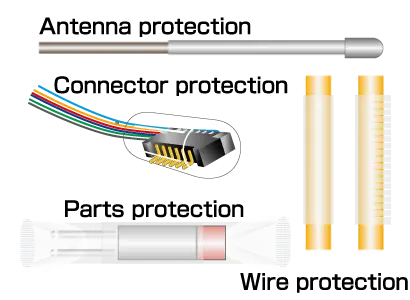

Tube Caps

Tubes and caps that can be made thinner by 0.1㎜, which cannot be done with molded products.It is used for parts protection and jigs that pass parts through narrow spaces.

Edge processing of flares, shells, seals, etc. is possible.